Our Projects

Our Waste Heat Recovery projects have helped a diverse range of industries increase energy efficiency, reproduce energy for indigenous consumption, decrease air pollution and bring down the production of greenhouse gases.

Explore our projects below

HEAT RECOVERY STEAM GENERATORS (HRSG)

- Heat Recovery Steam Generators behind a Gas Turbine can be operated either in the cogeneration mode or combined cycle mode. Cogeneration mode is predominantly used in the process industries and supplies steam for various process applications. For Combined Cycle Power Plant (CCPP), Greens supply HRSG’s of Single and Dual Pressure for various frame sizes of gas turbines ranging from 1MW to 75MW. The units are supplied in harps as well as in modules

- Greens designed, manufactured, supplied and installed HRSGs on Turnkey basis for a CCPP with a configuration of 2GT + 2HSRG + 1STG

- HP Steam Generation : 113 TPH at 98 bar(a) at 538 +/- 5 Deg.C

- LP Steam Generation : 13.6 TPH at 9 bar(a) at 275 +/- 5 Deg.C

- Steam to Deaerator : 1.08 TPH

- CPH Water Flow : 130 TPH at 12 bar(g) at 51 Deg.C

- Each HRSG was designed in 4 modules.

- Module 1 – HP HTSH, HP LTSH & HP Evaporator

Module 2 – HP Economiser 2, LP SHTR & HP Economiser 1

Module 3 – LP Evaporator

Module 4 – Condensate Preheater

HAZARDOUS WASTE HEAT RECOVERY BOILERS

- Some industrial processes produce waste, which can be hazardous and detrimental to public health and the environment if not managed properly. Hazardous wastes are generated in the production of cosmetics, detergents, pharmaceuticals, pesticides, paint etc.

- Many companies have made significant progress in recent years to reduce or recycle hazardous wastes from their processes through incinerators. Incineration converts waste into ash and fuel gas. Greens, with their Waste Heat Recovery Boiler (WHRB) technology, have gained expertise in handling such high temperature gases exhausted from incinerators. Steam generated thus finds usage in process or power generation.

- The WHRB is designed to extract required heat from the exhaust gas of Hazardous Waste Incinerator. For this purpose flue gas from Incinerator is arranged in a direction counter to water / steam circuit of Water Wall Panel and parallel to circuit of Evaporator. The exhaust gas from SCC to GCT duct tapped to enter into WHRB inlet.

- The gas travels through the first pass of Water Wall Panel and then travel through evaporator modules. After that the gas is allowed to enter to the existing GCT. The steam drum is connected to Water Wall Panel Header and Evaporator bottom Header through down comer and Risers. It receives feed-water from the Boiler Feed Water Pump to maintain positive water supply in Water Wall Panel and Evaporator Modules. Drum receives the mixture of steam and water from the evaporator modules as well as water wall panel by heat transfer. After separating water from the steam / water mixture at drum, the saturated steam is supplied through MSSV to the heating process.

CEMENT WASTE HEAT RECOVERY BOILERS

- Most Portland cement is made in a rotary kiln. In modern works, the blended raw material enters the kiln via the pre-heater tower. An integral part of the process is a heat exchanger called a ‘suspension preheater’. This is a tower with a series of cyclones in which fast-moving hot gases keep the meal powder suspended in air.

- Throughout the process, the meal gets hotter and the gas gets cooler until the meal is at almost the same temperature as the gas. When the gas exits the kiln, it is still at a high temperature and is made to pass through the WHRB.

Such gases are highly dust laden and Greens developed not only the WHRB but also an effective hammering device and mechanism to ensure continuous cleaning and maximum heat recovery.

On the other side, when the clinker is out, to bring down its temperature inert gas or generally air is used to quench it. The hot air after the quenching needs to be cooled and Greens WHRB are very apt to handle such gases with abrasive particles.

GLASS FURNACE WASTE HEAT RECOVERY BOILERS

- Modern glass formulations are often complex and varied, combining powders with raw materials to achieve very specific glass properties. Producing these specialty glasses requires a glass furnace with accurate temperature capability above 1500oC. This process results in exhausting the gases at high temperature and carries abrasive particles.

- Greens gives every care and attention to handle this type of gas in the WHRB to produce saturated steam which in turn is used for Tank Farm Heating, Line Tracing etc. To boost furnace capacities, the WHRB incorporates a superheater for combined heat and power.

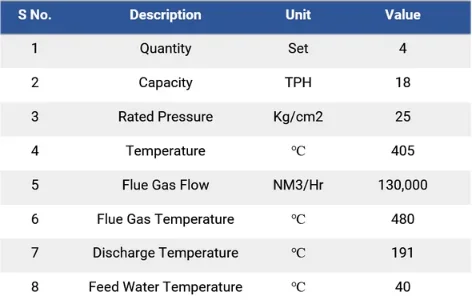

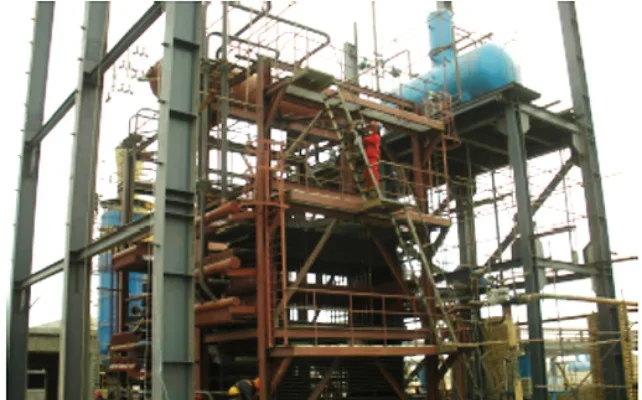

- Greens did a bespoke design on a 100,000 MT/A Glass plant with four 800 T/D batteries. One 12 MW Waste Heat Recovery Power Plant was built, which could supply 20% power consumption of the Glass Melting Furnace.

- Greens has engineered, manufactured, fabricated and supplied 4 sets Flue Gas Waste Heat Recovery Boilers for the plant to generate up to 72 T/H superheated steam @ 25 kg/cm2, 400℃

COKE OVEN WASTE HEAT RECOVERY BOILERS

- In the process of producing coking coal, when the coal is burnt at high temperature in an oven with reduced oxygen, carbonisation starts and produces volatile matter, which burns inside the partially closed side door. Carbonisation proceeds from top to bottom and is completed in two to three days. Heat is supplied by the burning volatile matter and by-products are recovered. The exhaust gases, which are at a higher temperature, are allowed to escape to the atmosphere.

- Greens supplies specially designed WHRB to capture heat energy from the exhaust gases to generate power. The WHRB for Coke Dry Quenching process is supplied in modules for quick and easy site installations.

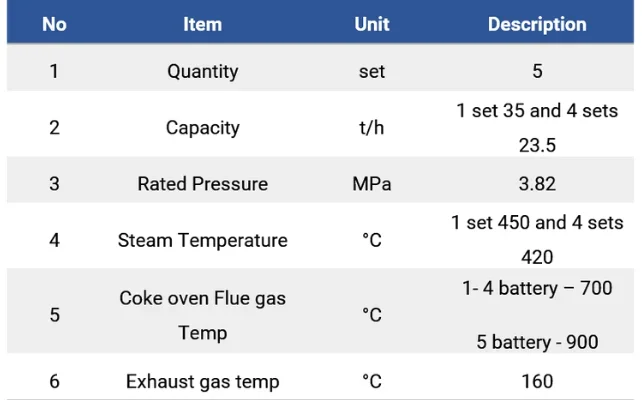

- On a 0.6 Million TPA coke oven plant with 4 batteries of 34 ovens each and the 5th battery having 40 ovens, Greens built a 30 MW power plant equipped with 5 sets of waste heat recovery boilers and 2 sets of turbines.

Greens designed, manufactured and supplied all the boilers for the project and sourced the steam turbines and balance of plant from consortium partners

GAS HEAT EXCHANGER

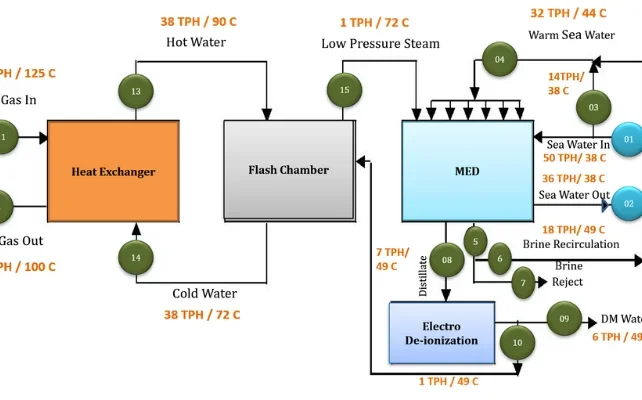

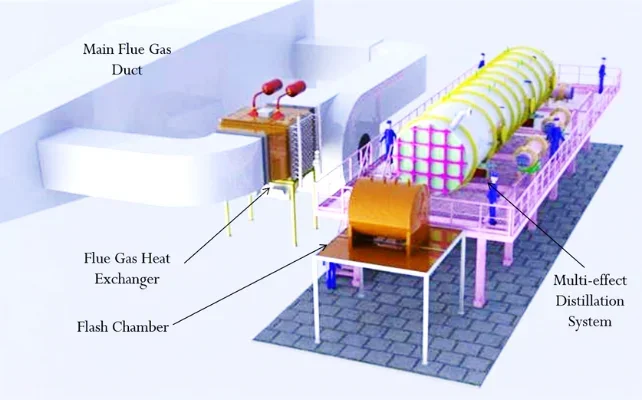

- An innovative, low carbon intensive desalination system. Waste heat from exiting flue gas in a fossil powered power plant is utilised for distillation of sea water instead of steam or electricity as used in conventional desalination plants.

- Cost effective, sustainable and environment friendly

technology - High yield and plant availability

- Modular and scalable design